What Are the Most Common Mistakes in Marine Exhaust Installation, and How Can Customization Help?

When it comes to optimizing your vessel’s performance and safety, a properly installed marine exhaust system is essential. Marine exhaust systems are critical components that not only reduce engine noise and emissions but also prevent dangerous fumes from accumulating in living areas. However, many boat owners and installers fall into common pitfalls during installation that compromise the exhaust’s efficiency, durability, and safety.

Centek mufflers, a leader in marine exhaust technology, often sees these issues firsthand. The good news is that many of these mistakes can be avoided by choosing custom marine exhaust solutions tailored specifically for your boat’s unique configuration and operating conditions.

In this blog, we’ll explore the most common mistakes made during marine exhaust installation and explain how customization—leveraging expert products like marine exhaust elbows, exhaust risers, and boat ventilation systems—can deliver a safer, more reliable boating experience.

Understanding Marine Exhaust Systems: The Basics

Before diving into installation errors, it’s important to understand the main components of marine exhaust systems and their functions:

- Marine Exhaust Systems: These systems direct engine exhaust gases safely out of the boat. They typically include mufflers, elbows, risers, hoses, and ventilation components.

- Centek Mufflers: These specialized mufflers reduce noise and backpressure, providing quieter operation and improved engine efficiency.

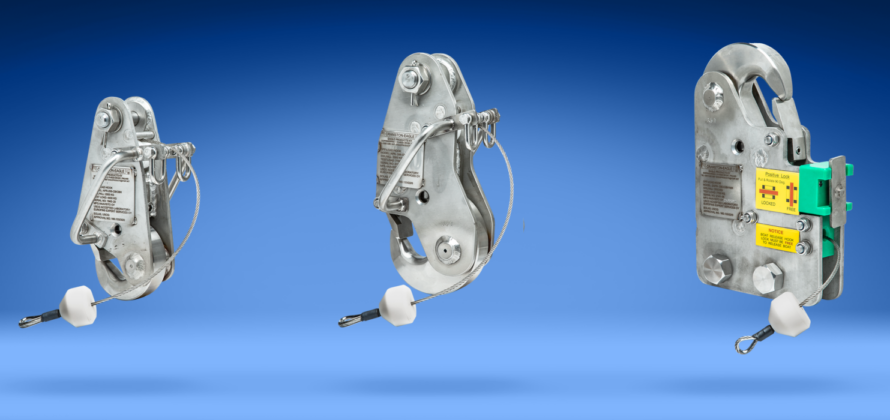

- Marine Exhaust Elbows: These fittings connect the exhaust manifold to the exhaust hose and help route gases while preventing water backflow.

- Exhaust Risers: Often made of corrosion-resistant materials, risers elevate the exhaust outlet above the waterline, reducing water intrusion risk.

- Boat Ventilation Systems: These systems circulate air to prevent heat and fume buildup in the engine compartment.

Using Incorrect Marine Exhaust Elbows and Risers

One of the most frequent errors in marine exhaust installation involves using the wrong type or poorly fitting marine exhaust elbows and exhaust risers.

Why It Matters

Marine exhaust elbows must have the right bend radius and material properties to withstand engine heat and saltwater corrosion. An incorrect elbow can cause restrictions, leading to backpressure that reduces engine performance and increases fuel consumption. Likewise, an improperly sized or installed exhaust riser may allow seawater to backflow into the engine, causing catastrophic damage.

How Customization Helps

Custom marine exhaust solutions, like those offered by Centek, provide elbows and risers engineered for specific engine models and boat layouts. This precise fit ensures proper flow dynamics, reduces backpressure, and prevents water intrusion.

Table: Common Issues with Standard vs. Custom Marine Exhaust Elbows and Risers

| Issue | Standard Fittings | Custom Marine Exhaust Components |

|---|---|---|

| Fitment | Often generic, may not fit well | Designed to match engine & hull specifications |

| Material Durability | Standard metals prone to corrosion | Corrosion-resistant alloys or composites |

| Exhaust Flow Efficiency | Potential flow restrictions | Optimized bend radius for smooth flow |

| Water Backflow Risk | Higher risk with poor riser design | Proper riser height and angle to prevent water intrusion |

Neglecting Proper Ventilation in Engine Compartments

Boat ventilation systems are often overlooked during exhaust installation, yet they are vital for safe operation.

Why It Matters

Engine compartments generate heat and exhaust fumes. Without adequate ventilation, these can accumulate, increasing the risk of fire, corrosion, and health hazards due to carbon monoxide buildup. Poor ventilation also contributes to accelerated engine wear and inefficient combustion.

How Customization Helps

Custom boat ventilation systems are designed to fit the unique engine room layout, ensuring optimal airflow. A tailored system integrates well with the exhaust setup, facilitating effective heat dissipation and fume extraction.

For example, integrating custom marine exhaust systems with proper ventilation ducts and blowers improves overall vessel safety. Marine professionals often recommend coordinating exhaust and ventilation design to prevent conflicting airflow patterns that can trap exhaust gases.

Improper Installation of Centek Mufflers

The Centek muffler is a top choice for quiet and efficient marine exhaust, but incorrect installation can diminish its benefits.

Why It Matters

If a muffler is installed incorrectly — such as misaligned mounting, wrong orientation, or inadequate sealing — it can cause leaks, vibration issues, and noise problems. This leads to engine inefficiency and discomfort for passengers.

How Customization Helps

Custom marine exhaust installation ensures the muffler fits perfectly within the system, maximizing noise reduction and durability. Since each boat’s engine compartment and exhaust path differ, customizing the muffler placement and connection points eliminates vibration and leak issues.

Moreover, a tailored Centek muffler setup can incorporate features like water injection cooling tailored to your engine type, which further reduces noise and temperature.

Using Standard Exhaust Hose Lengths Without Adaptation

Many installers use off-the-shelf exhaust hoses of fixed lengths rather than customizing lengths for their specific system.

Why It Matters

Excess hose length can cause unnecessary bends and loops, restricting exhaust flow. Too short a hose creates tension and stress on fittings, risking leaks or hose failure. Both scenarios impact engine efficiency and risk water intrusion.

How Customization Helps

Custom marine exhaust system designs include properly-sized hoses which ensures the hoses fit the exact run length and routing of your boat’s exhaust system. This precision eliminates excessive bends and tension points, improving durability and exhaust flow.

Coupled with custom elbows and risers, this creates an integrated exhaust path optimized for your boat’s design.

Failing to Account for Corrosion and Marine Environment

Marine exhaust components face constant exposure to saltwater and harsh conditions, yet some installations neglect using corrosion-resistant materials or protective coatings.

Why It Matters

Corrosion weakens exhaust elbows, risers, and mufflers, leading to leaks, failures, and costly repairs. Rusty components also negatively affect exhaust flow and noise.

How Customization Helps

Custom marine exhaust components from reputable manufacturers like Centek use fiberglass-reinforced plastic which is lightweight and corrosion-resistant – ideal for marine environments. Fiberglass-reinforced plastic will no warp or melt when exposed to heat, which is often observed in plastic or rubber mufflers.

By specifying custom corrosion-resistant parts, boat owners extend system longevity and reduce maintenance costs.

Why Choose Custom Marine Exhaust Solutions?

Custom marine exhaust solutions aren’t just about replacing parts — they represent a holistic approach to optimizing your vessel’s exhaust system. Here’s why customization matters:

- Tailored Fit: Custom components are designed together to fit perfectly, reducing installation issues and maximizing performance.

- Enhanced Safety: Correctly-designed exhaust paths prevent water backflow and gas leaks.

- Noise Reduction: Custom mufflers and elbows minimize engine noise for a quieter ride.

- Durability: High-quality fiberglass-reinforced plastic materials resist corrosion or warping in harsh marine environments.

- Improved Efficiency: Proper flow dynamics reduce engine backpressure and improve fuel economy.

- Compliance: Custom systems can be designed to meet environmental and safety regulations.

How to Get Started with Custom Marine Exhaust Installation

- Assessment: Have a marine expert inspect your boat’s current exhaust system and engine layout.

- Consultation: Discuss your boating habits, engine specs, and any performance or noise concerns.

- Design: Work with specialists to design a custom system that includes Centek mufflers, marine exhaust elbows, risers, and ventilation components.

- Fabrication: Custom parts are manufactured or selected based on your boat’s specific requirements.

- Professional Installation: Have your system installed by certified marine technicians to ensure proper fit and function.

- Testing & Maintenance: Regularly test your exhaust system for leaks, corrosion, and proper ventilation, especially after installation.

Final Thoughts

Marine exhaust installation is not a one-size-fits-all process. Common mistakes like using incorrect elbows or risers, neglecting ventilation, improper muffler setup, and ignoring corrosion risks can compromise your vessel’s safety and performance. Custom marine exhaust systems, such as those from Centek, are designed to eliminate these problems by providing precise, durable, and efficient solutions tailored to your boat.

If you want to protect your investment, ensure safety, and enjoy quiet, efficient engine operation, explore the benefits of a custom marine exhaust system. Trust Centek mufflers and expertly designed exhaust components to provide the ultimate marine exhaust experience.

Frequently Asked Questions

Q1: Why is a custom marine exhaust better than a standard one?

A: Custom exhausts are designed to match your boat’s specific engine and layout, providing better fit, improved flow, and increased durability.

Q2: Can improper exhaust installation damage my engine?

A: Yes, issues like backpressure or water backflow caused by poor installation can seriously damage the engine.

Q3: How often should marine exhaust components be inspected?

A: It’s best to inspect your exhaust system annually or after harsh conditions to detect corrosion or leaks early.

Q4: What materials are best for marine exhaust mufflers, elbows and risers?

A The majority of Centek marine mufflers and elbows are made using fiberglass-reinforced plastic for durability in the harsh marine environment. Risers are made of weldable stainless steel and coated in our proprietary hardcoat for maximum durability at sea.