Beyond the Vent: How Motorized Louvers & Moisture Eliminators Protect High Value Engines

Marine engines are the heart of any vessel, powering everything from small yachts to large commercial ships. However, operating in harsh marine environments exposes these high value assets to salt spray, moisture, and extreme temperatures, which can lead to corrosion, reduced efficiency, and costly repairs.

Proper ventilation is critical to maintaining engine performance and longevity, and components like motorized louvers and moisture eliminators play a pivotal role. This guide explores how these systems, paired with marine ventilation fans and blowers, safeguard engines while ensuring compliance with safety standards. Learn how solutions from Centek Marine enhance vessel performance in challenging conditions.

The Importance of Marine Ventilation Systems

Marine environments are uniquely demanding, with constant exposure to saltwater, humidity, and fluctuating temperatures. Without adequate ventilation, engine rooms can become hot, humid spaces where moisture and heat accumulate, leading to:

- Corrosion: Salt laden air can corrode engine components, reducing lifespan.

- Overheating: Inadequate airflow causes engines to overheat, lowering efficiency and risking failure.

- Fume Buildup: Poor ventilation can trap flammable gases, increasing the risk of fires or explosions.

A well designed ventilation system, including marine ventilation fans, boat exhaust fans, and ventilation blowers, ensures proper airflow, temperature control, and moisture management. Components like motorized louvers and moisture eliminators enhance these systems by addressing specific environmental challenges.

Why Engine Room Ventilation Matters

Engine rooms require a steady supply of cool, clean air for combustion and cooling. According to industry data, inadequate ventilation can reduce engine efficiency by up to 20% and shorten component lifespan by years. Marine ventilation fans and blowers, such as Delta-T Systems equipment offered by Centek Marine, deliver consistent airflow to maintain optimal operating conditions, protecting high value engines from premature wear.

The Role of Motorized Louvers in Marine Ventilation

Motorized louvers are adjustable slats installed in ventilation systems to control airflow and protect engine rooms from external elements. Unlike static vents, motorized louvers can open or close automatically, offering dynamic control over air intake and exhaust. Here’s how they contribute to engine protection:

1. Regulating Airflow

Motorized louvers adjust based on engine room demand, ensuring sufficient combustion air during operation and reducing airflow when the engine is idle. This prevents overcooling, which can cause condensation, and maintains optimal temperatures.

2. Blocking Water and Debris

In rough seas or storms, motorized louvers can close to prevent water, salt spray, and debris from entering the engine room. This is critical in coastal regions where storms are frequent, as water ingress can corrode sensitive components.

3. Enhancing Safety

In the event of a fire, motorized louvers can close to starve the fire of oxygen, working in tandem with fire dampers. This rapid response, as noted in Centek Marine systems, helps comply with U.S. Coast Guard and SOLAS safety standards.

4. Energy Efficiency

By precisely controlling airflow, motorized louvers reduce the workload on marine ventilation fans, thereby lowering energy consumption. This is especially valuable for vessels aiming to minimize fuel costs.

Centek Marine offers motorized louvers integrated with their ventilation systems, designed to withstand marine conditions with corrosion resistant materials.

Moisture Eliminators: A Critical Defense Against Corrosion

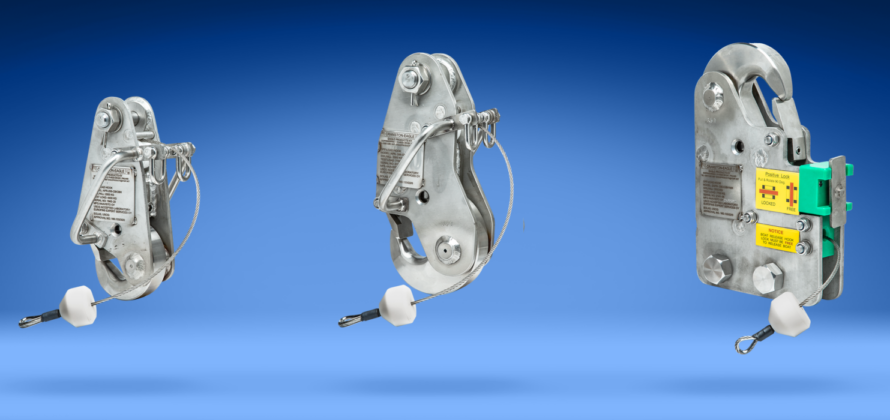

Moisture eliminators, also known as mist eliminators, are impingement type separators designed to remove salt spray and water from incoming air. In marine environments, where humidity and saltwater are constant threats, these devices are essential for protecting engines. Here’s how they work and why they matter:

1. Removing Salt and Water

Moisture eliminators use a unique hook and flow design to capture over 97% of salt spray and water droplets from airflow, as per Centek Marine specifications. This ensures that only dry, clean air reaches the engine, reducing corrosion risks.

2. Maintaining Engine Efficiency

Wet air can disrupt combustion, leading to incomplete fuel burn and reduced power output. By delivering dry air, moisture eliminators help engines operate at peak efficiency, improving fuel economy and performance.

3. Extending Component Lifespan

Salt and moisture accelerate corrosion of engine components, such as pistons, valves, and turbochargers. Moisture eliminators protect these parts, potentially extending engine life by years and reducing maintenance costs.

4. Versatile Installation

Designed for vertical installation with horizontal airflow, moisture eliminators are available in plastic or aluminum, with optional powder coating for added durability. They integrate seamlessly with marine blower fans as part of a complete ventilation system.

Centek Marine provides moisture eliminators tailored to vessel specifications, ensuring optimal protection in harsh marine environments.

The Role of Marine Ventilation Fans and Blowers

Marine ventilation fans and blowers are the backbone of engine room ventilation, working alongside louvers and moisture eliminators to ensure a steady supply of clean, cool air. Centek Marine offers a range of Delta-T Systems options, including:

Standard Marine Axial Fans

These fans feature flanged steel housings with epoxy coating and polypropylene composite blades for corrosion resistance and low noise. They are ideal for continuous duty applications, providing flow rates tailored to engine needs.

Premium Marine Axial Fans

Built with welded marine grade aluminum housings, these fans offer lightweight durability and are equipped with high efficiency NEMA Premium motors for quiet, reliable performance.

Ignition Protected DC Axial Fans

Designed for small vessels, these compact fans use glass filled nylon shrouds for durability and are ignition protected to meet stringent safety standards like ISO 8846.

Centrifugal Blowers

Tailored for marine applications, these blowers support galley fume extraction, head air extraction, and engine room ventilation, with optional CE or I EEE 45 certification.

These fans and blowers ensure consistent airflow, complementing motorized louvers and moisture eliminators to create a comprehensive ventilation system.

Best Practices for Integrating Ventilation Components

To maximize engine protection, vessel owners and builders should follow these best practices:

1. Customize to Vessel Needs

Work with engineers to design ventilation systems tailored to your vessel’s size, engine type, and operating conditions. Centek Marine offers custom fan sizes and configurations to meet specific requirements.

2. Prioritize Corrosion Resistant Materials

Choose components made from marine grade aluminum, stainless steel, or UV protected plastics to withstand saltwater exposure. This ensures long-term durability and reduces maintenance costs.

3. Ensure Compliance with Safety Standards

Select fans and blowers that meet U.S. Coast Guard, ISO, or SOLAS standards, especially for ignition protection and fire safety. Motorized louvers should integrate with fire dampers for rapid response.

4. Optimize Airflow Placement

Position air intake low and away from heat sources, with exhaust vents high to remove hot air. Use airflow diverters to direct air to critical engine components, as recommended by Centek Marine.

5. Regular Maintenance

Inspect louvers, moisture eliminators, and fans regularly to ensure proper function. Clean moisture eliminators to prevent clogging and check motorized louvers for smooth operation.

Conclusion

Motorized louvers and moisture eliminators, paired with marine ventilation fans and blowers, are essential for protecting high value engines in harsh marine environments. By regulating airflow, removing moisture, and ensuring safety, these components extend engine lifespan, improve efficiency, and reduce maintenance costs.

Vessel owners and builders can rely on Centek Marine for durable, customizable solutions that meet stringent safety standards. Investing in a comprehensive ventilation system is not just about compliance, it’s about safeguarding your vessel’s most critical asset.

FAQs About Marine Ventilation Systems

What is the role of motorized louvers in marine ventilation?

Motorized louvers regulate airflow, block water and debris, and enhance safety by closing during fires, ensuring optimal engine room conditions.

How do moisture eliminators protect marine engines?

Moisture eliminators remove over 97% of salt spray and water from incoming air, reducing corrosion and improving combustion efficiency.

What types of marine ventilation fans are available?

Options include standard and premium axial fans, inline AC duct fans, ignition protected DC axial fans, and centrifugal blowers, each suited to specific vessel needs.

Why is corrosion resistance important in marine ventilation?

Saltwater and humidity accelerate corrosion, which can damage engines. Components like those from Centek Marine use marine grade materials to ensure durability.

How do I choose the right ventilation system for my vessel?

Consult with engineers to select fans, blowers, and accessories tailored to your vessel’s size, engine type, and operating environment. Centek Marine offers custom solutions.

Can ventilation systems improve fuel efficiency?

Yes, by providing clean, cool air, ventilation systems optimize combustion, reducing fuel waste and improving engine performance