The High Cost of Poor Airflow: Optimizing Your Commercial Vessel’s Ventilation System

Commercial vessels, from cargo ships to luxury yachts, rely on robust engine performance to operate efficiently in demanding marine environments. However, poor airflow in engine rooms can lead to significant operational and financial setbacks, including increased maintenance costs, reduced fuel efficiency, and even catastrophic engine failure. Optimizing boat ventilation systems is critical to ensuring engine longevity, crew safety, and regulatory compliance. This guide explores the consequences of inadequate marine engine room ventilation and provides actionable strategies for designing effective ventilation control systems. Discover how Centek Marine delivers tailored solutions to enhance vessel performance.

The Critical Role of Marine Engine Room Ventilation

Marine engine rooms house powerful engines and generators that require a steady supply of clean, cool air for combustion and cooling. Without proper ventilation, engine rooms become hot, humid environments that compromise performance and safety. Key functions of marine ventilation systems include:

- Combustion Air Supply: Providing oxygen for efficient fuel burning.

- Temperature Regulation: Removing excess heat to prevent overheating.

- Moisture Control: Reducing humidity and salt spray to prevent corrosion.

- Fume Extraction: Eliminating harmful gases to ensure crew safety and compliance with regulations.

According to industry studies, inadequate ventilation can reduce engine efficiency by up to 20% and increase maintenance costs significantly. Centek Marine offers comprehensive engine ventilation systems designed to address these challenges.

Consequences of Poor Airflow in Commercial Vessels

Poorly designed or maintained ventilation systems can have severe consequences for commercial vessels. Understanding these risks highlights the importance of investing in optimized marine engine room ventilation.

1. Increased Maintenance and Fuel Costs

Insufficient airflow restricts combustion, forcing engines to work harder and consume more fuel. This inefficiency can increase fuel costs by 10 to 15%, according to marine engineering data. Additionally, trapped heat and moisture accelerate wear on components, leading to frequent repairs and replacements.

2. Engine Performance Issues

Engines deprived of adequate air produce incomplete combustion, reducing power output and causing performance issues. This can lead to delays in operations, impacting commercial schedules and profitability.

3. Corrosion from Salt and Moisture

Marine environments expose engines to saltwater and humidity, which cause corrosion if not properly managed. Poor ventilation allows moisture to accumulate, damaging critical components like turbochargers and pistons, potentially costing thousands in repairs.

4. Safety Hazards

Inadequate ventilation can trap flammable gases, increasing the risk of fires or explosions. High temperatures and noise levels also pose risks to crew safety, violating U.S. Coast Guard and SOLAS standards.

5. Warranty and Compliance Issues

Many engine manufacturers require specific airflow conditions to maintain warranty validity. Poor ventilation can void warranties and lead to non-compliance with maritime regulations, resulting in fines or operational restrictions.

6. Risk of Catastrophic Failure

In extreme cases, overheating and fume buildup can cause engine failure, halting operations and requiring costly overhauls. For commercial vessels, downtime can result in significant revenue losses.

Centek Marine addresses these risks with custom engineered ventilation solutions tailored to vessel specifications.

Components of an Effective Ventilation System

Optimizing marine engine room ventilation requires integrating key components that work together to ensure proper airflow, temperature control, and safety. Centek Marine offers a range of products designed for these purposes.

Marine Ventilation Fans and Blowers

Fans and blowers are the backbone of boat ventilation systems, delivering consistent airflow for combustion and cooling. Options include:

- AC Axial Fans: High efficiency fans for large engine rooms, with corrosion resistant housings.

- DC Axial Fans: Compact, ignition protected fans for smaller vessels.

- Centrifugal Blowers: Ideal for fume extraction and auxiliary ventilation in galleys or crew spaces.

These components are built for continuous duty in harsh marine environments, ensuring reliability and efficiency.

Fire Dampers

Fire dampers close rapidly during a fire to restrict oxygen and prevent flame spread. A60 rated dampers, offered by Centek Marine, provide 60 minutes of fire resistance and comply with U.S. Coast Guard and MED standards.

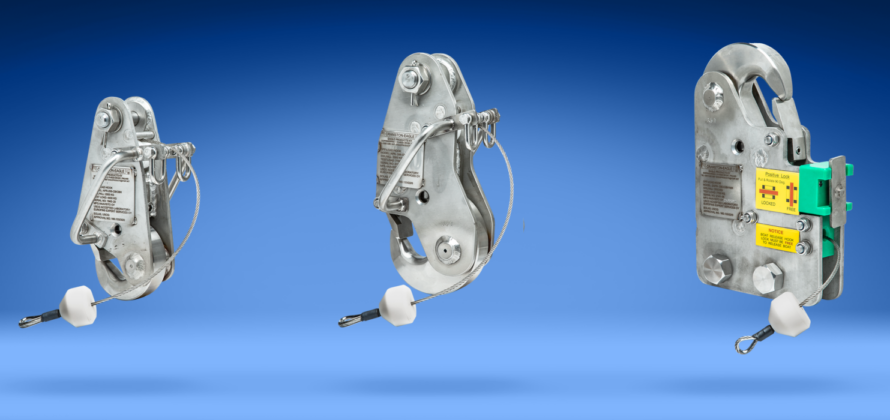

Moisture Eliminators

Moisture eliminators remove over 97% of salt spray and water from incoming air, protecting engines from corrosion. Available in plastic or aluminum, these devices ensure clean, dry air reaches critical components.

Ventilation Control Systems

Advanced control systems automate fan speed, damper operation, and airflow based on engine demand. These systems optimize energy use and maintain ideal conditions, reducing operational costs.

Centek Marine integrates these components into cohesive systems, customized to meet specific vessel requirements.

Best Practices for Optimizing Ventilation Systems

To mitigate the risks of poor airflow and enhance vessel performance, shipyards and vessel operators should follow these best practices:

1. Conduct a Ventilation Assessment

Work with engineers to assess engine heat and air requirements. Centek Marine uses an extensive database of engine specifications and over 20,000 installations to design tailored systems.

2. Choose Corrosion Resistant Materials

Select components made from marine grade aluminum, stainless steel, or UV protected plastics to withstand saltwater and humidity. This ensures long term durability and reduces maintenance needs.

3. Integrate Advanced Control Systems

Use ventilation control systems to automate airflow based on engine load and environmental conditions. This improves efficiency and reduces fuel consumption.

4. Ensure Regulatory Compliance

Select components that meet U.S. Coast Guard, SOLAS, and ISO standards, particularly for fire safety and ignition protection. A60 rated fire dampers are essential for commercial vessels.

5. Regular Maintenance and Inspections

Schedule routine inspections to clean moisture eliminators, check damper functionality, and ensure fans operate efficiently. This prevents performance issues and extends system lifespan.

6. Customize for Vessel Size and Type

Design ventilation systems to match the vessel’s engine size, operating environment, and usage. Centek Marine offers custom fan sizes and configurations for optimal performance.

Conclusion

Poor airflow in marine engine rooms can lead to increased costs, reduced performance, and safety risks, making optimized boat ventilation systems essential for commercial vessels. By integrating marine ventilation fans, fire dampers, moisture eliminators, and ventilation control systems, vessel operators can protect engines, ensure compliance, and improve efficiency.

Centek Marine provides custom engineered solutions tailored to the unique needs of commercial vessels, leveraging decades of experience and a comprehensive database of engine requirements. Invest in a robust engine ventilation system to safeguard your vessel’s performance and longevity.

FAQs About Marine Engine Room Ventilation

Why is proper ventilation critical for commercial vessels?

Proper ventilation ensures adequate combustion air, prevents overheating, reduces corrosion, and enhances safety, avoiding costly repairs and compliance issues.

What components are essential for marine ventilation systems?

Key components include marine ventilation fans, centrifugal blowers, fire dampers, moisture eliminators, and ventilation control systems.

How do moisture eliminators protect engines?

Moisture eliminators remove over 97% of salt spray and water, preventing corrosion and ensuring clean air for efficient combustion.

What are the benefits of ventilation control systems?

They automate airflow, optimize energy use, and maintain ideal engine room conditions, reducing fuel costs and improving performance.

How do fire dampers enhance safety?

Fire dampers close during a fire to restrict oxygen, preventing flame spread and ensuring compliance with U.S. Coast Guard and SOLAS standards.

Can ventilation systems be customized for specific vessels?

Yes, Centek Marine offers custom engineered systems based on engine specifications and vessel requirements.

How often should ventilation systems be maintained?

Regular inspections every 6 to 12 months ensure components like fans, dampers, and moisture eliminators function properly, preventing performance issues.