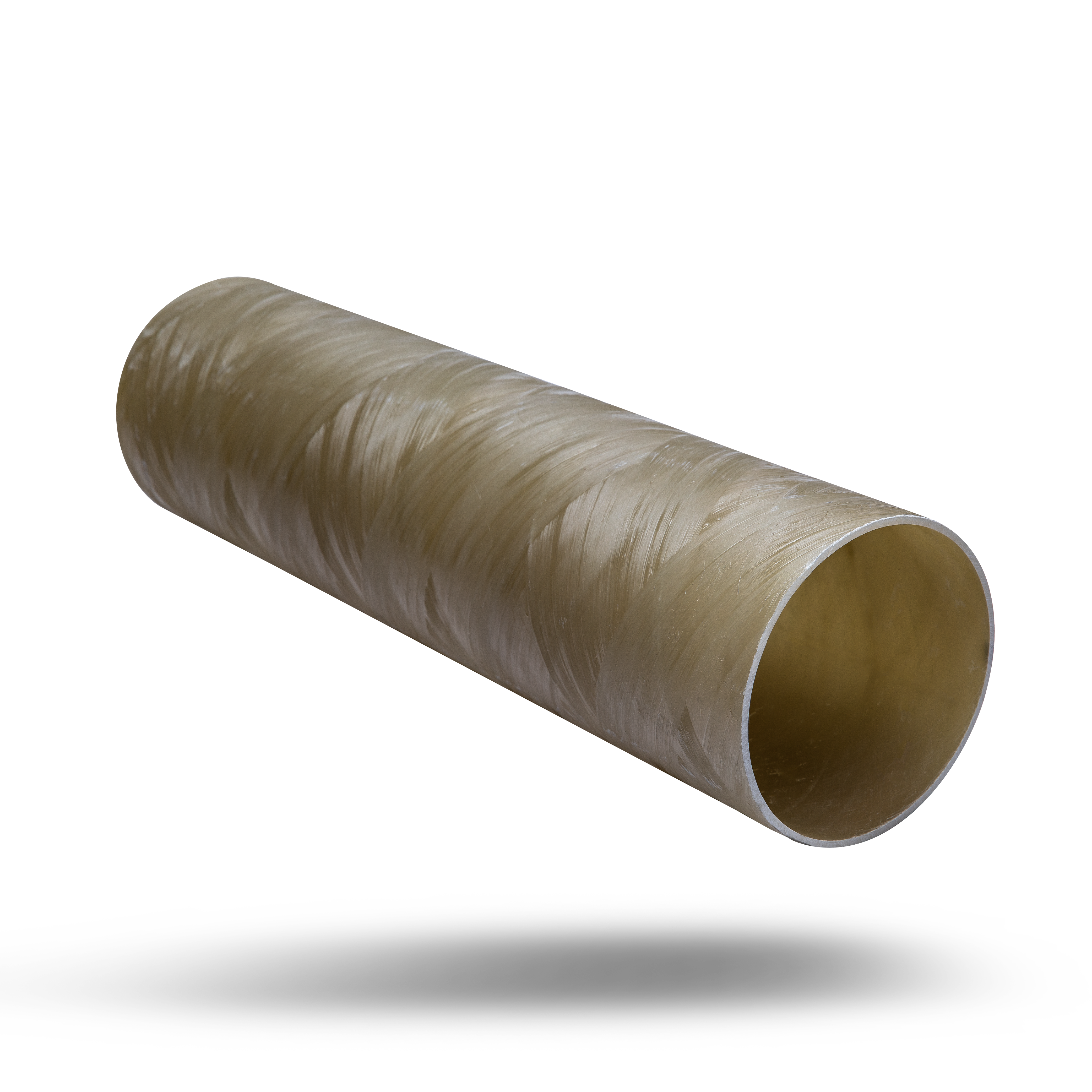

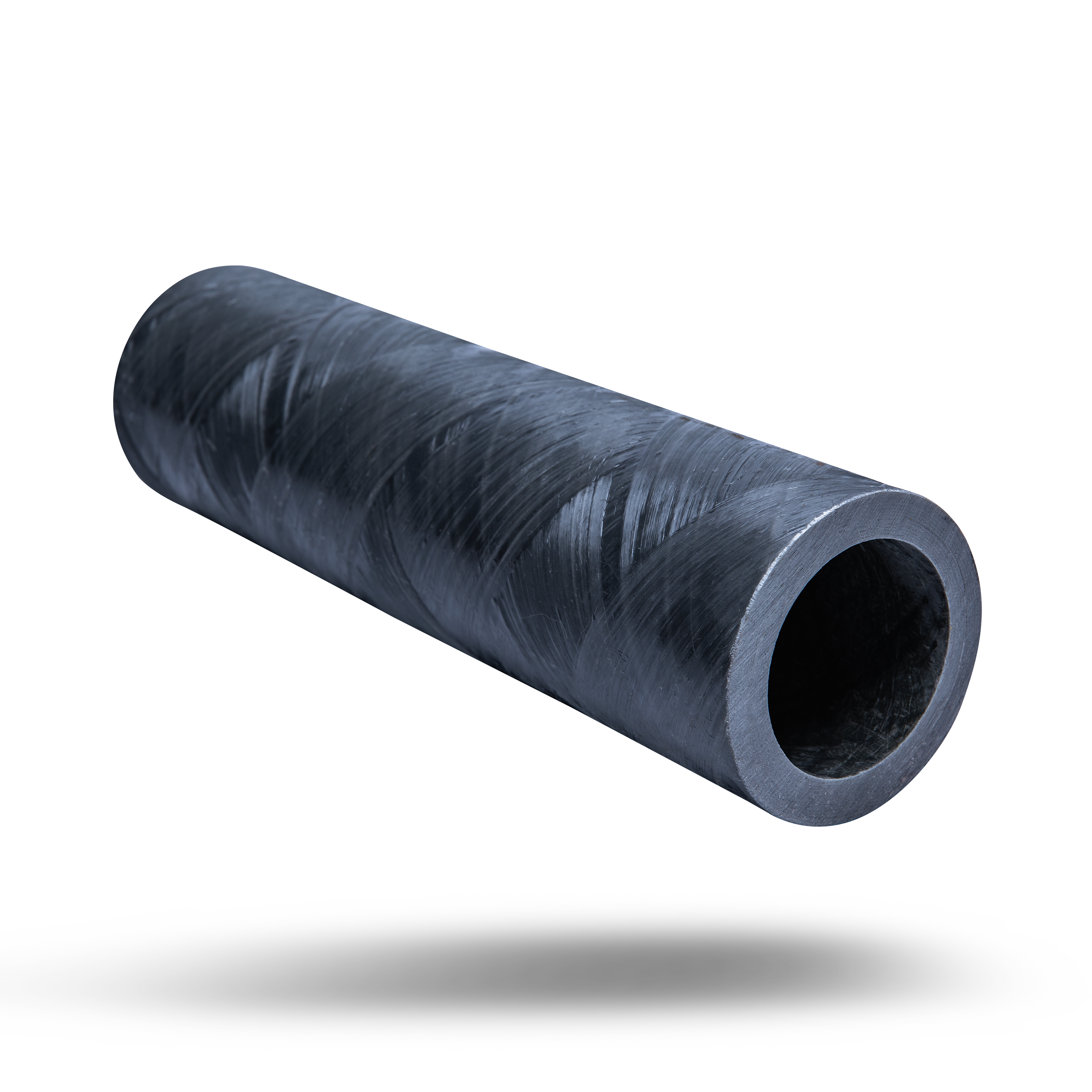

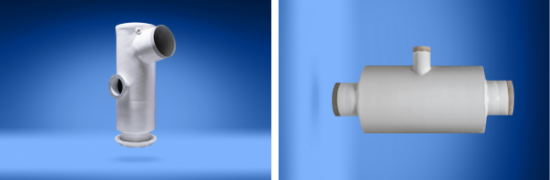

Vernatube

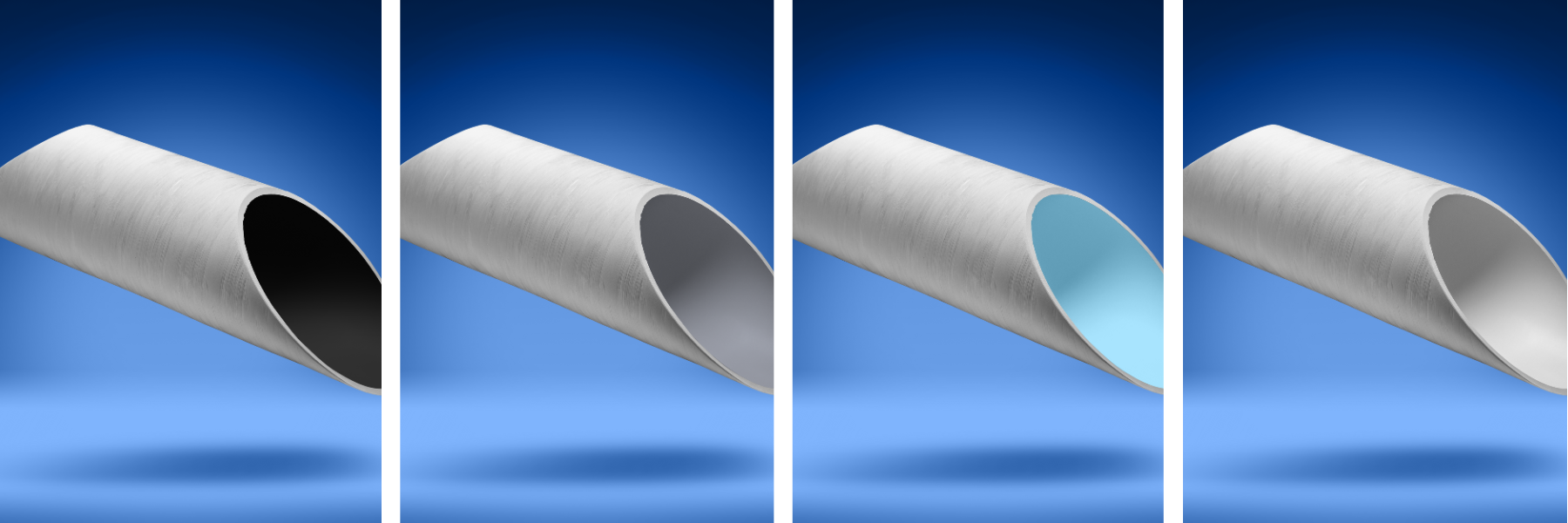

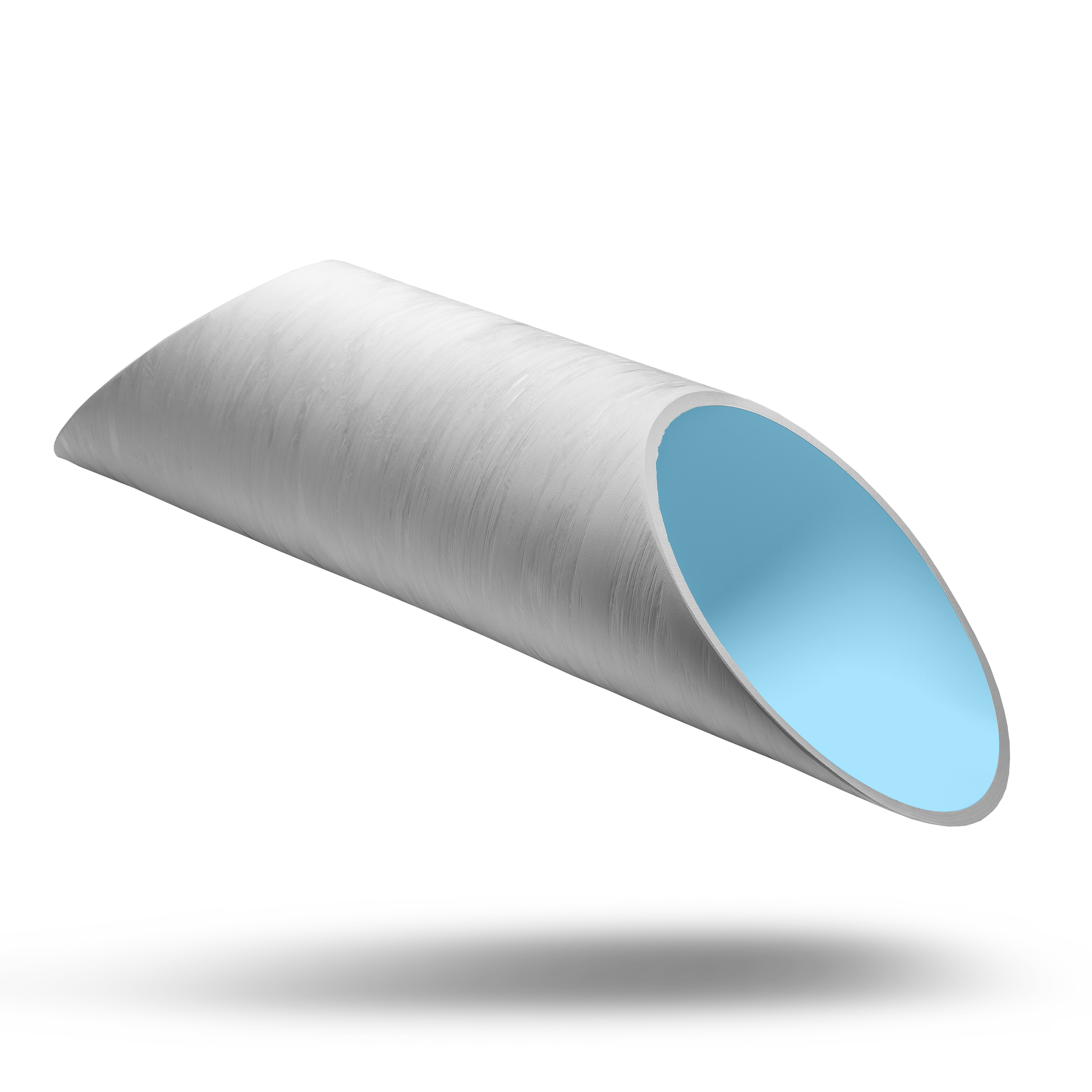

Vernatube® is a resin-impregnated glass filament wound tubing made exclusively with a fire-retardant resin formulated for high temperature applications. The smooth, resin-rich I.D. assures minimal restriction to exhaust gases and cooling water flowing through the tubing. Vernatube® exceeds values for the class of materials designated as ‘self-extinguishing’ per ASTM-D-635, UL94V-O, and the US Navy/USCG MIL-R-21607 and MIL-R-7575.